Gent Machine has a dedicated quality department to ensure that Gent Machine follows the ISO 9001 and IATF 16949 standards. Below is a list of techniques and controls we adhere to:

We employ Lighthouse Systems SPC Light version 4.51, statistical process control software that is used on the shop floor by the machine operators. Real time part measurements are uploaded in to the software program. The quality department monitors this data. We strive to achieve a 1.30 Cpk or higher. Dimensions that do not meet the 1.30 Cpk are stopped until the problem is fixed.

Quality and production personnel review every new job to ensure no detail is missed. ISIR samples can be provided as requested. We can also provide a full Level III PPAP with a Control Plan, Process Flow and FEMA

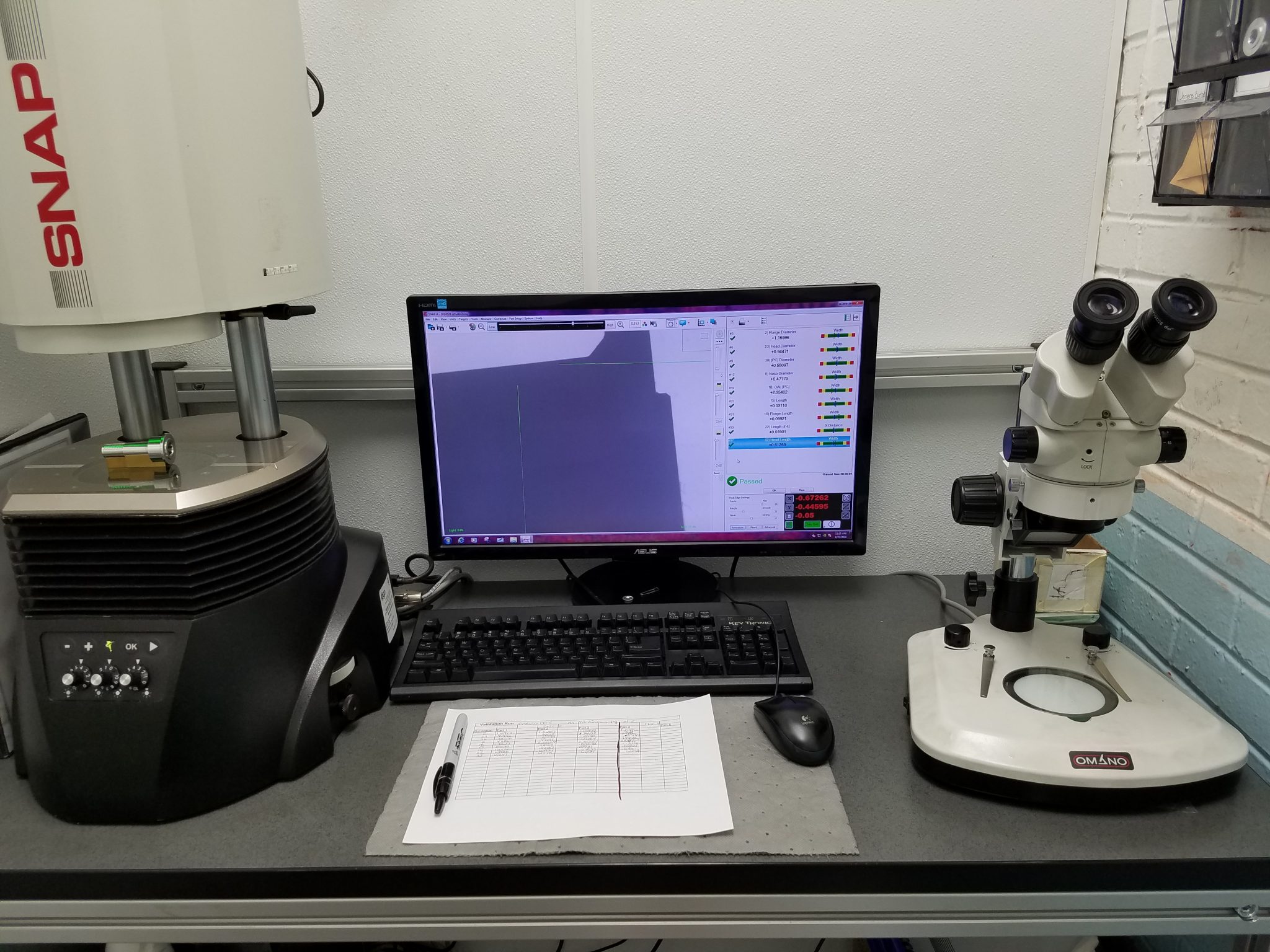

In process checks and final inspections are performed daily to ensure the products we are producing are made within the specifications. We have several comparators on the floor so employees can conveniently and routinely check parts for compliance.

Advance Gauge Control 2007, gauge control software is used to ensure all measurement devices used are capable. Each measurement device has an identification sticker listing the date the device was checked and the due date for the next check.

All documents in the facility are controlled. Prints released to the manufacturing floor are controlled and this is documented in a log. Obsolete prints are stamped Old print Do Not Use to ensure they are not used. A job traveler is included with each job package along with a blueprint and inspection card. A training session is held with the operator before a new job is run. During this session the operator will learn how to measure each dimension and the key characteristics of the part.

Please contact our quality department if you would like to learn more about quality at Gent Machine.

Website Developed by Cynexis

Website Developed by Cynexis